Silicon carbide drying project

Overview of the project:

Silicon carbide(SiC) is made of quartz sand, petroleum Coke(or coal Coke), and sawdust as raw materials by high temperature smelting of resistance furnaces. Silicon carbide also has rare minerals in nature, Mosangshi. Silicon carbide is also known as carbon silica. Among the non-oxide high-tech refractory materials such as C, N, and B, Silicon carbide is the most widely used and economical one. Can be called gold steel sand or fire resistant sand. At present, Silicon carbide produced in China is divided into black silicon carbide and green silicon carbide, both of which are hexagonal crystals with a specific gravity of 3.20 to 3.25 and a microhardness of 2840 to 3320 kg/m2.

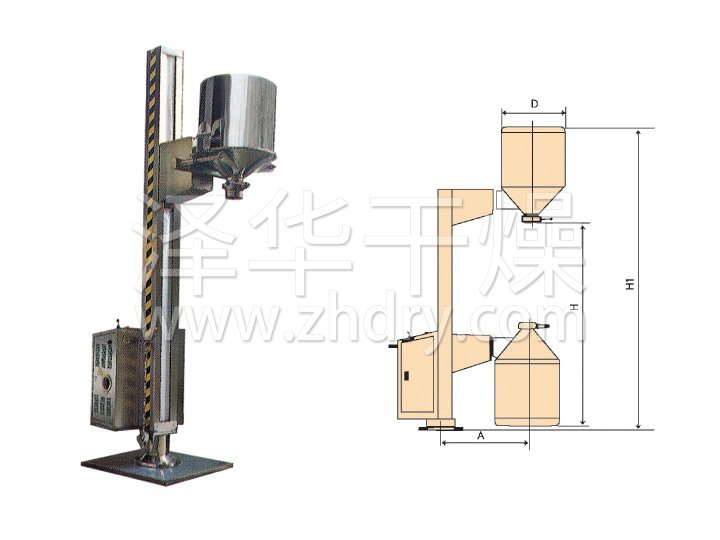

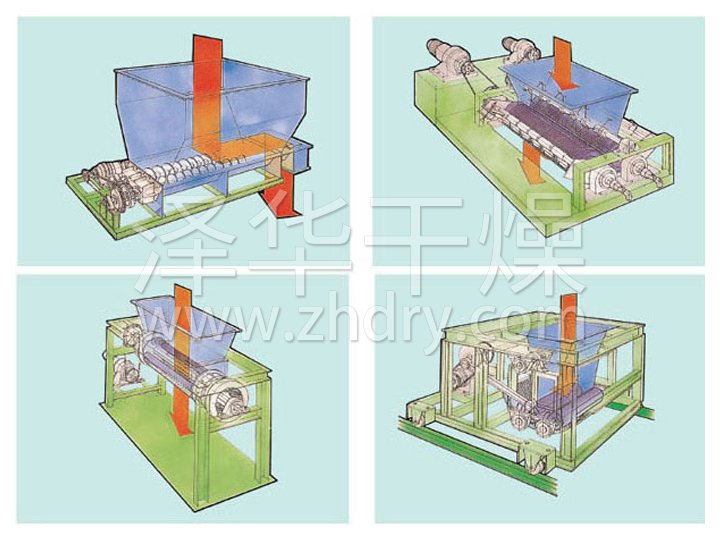

Equipment overview:

Silicon carbide drying production line is a new type of high efficiency fluidized drying equipment developed by our company to overcome static drying inefficiency and high consumption. In the design process, the machine fully combines the characteristics of airflow drying and other flow drying, enhances the length and avoids the short, so that the entire machine has a reasonable process structure and superior performance, and truly realizes the low consumption and high efficiency goal of fluidized drying.

This machine has a wide range of applications and can be used for Silicon Carbide, black silicon carbide, green carbon Silicon, black carbon Silicon micropowder, green silicon carbide micropowder, foam ceramic silicon carbide, refractory silicon carbide and other small powder materials. Dry. The equipment has high thermal efficiency, low energy consumption, small area, simple configuration, and convenient operation control.

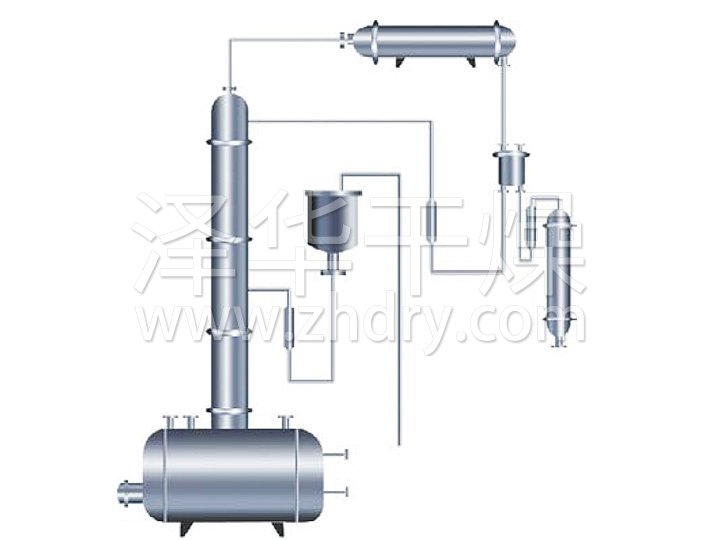

Working principles:

Hot air from the air inlet enters the mixing and crushing drying chamber from the bottom of the dryer at an appropriate spray speed, and strongly cuts, blows, and rotates the material, so that the material is particulate by centrifugation, shear, collision, and friction. Enhanced mass transfer heat transfer. At the bottom of the dryer, larger, wetter particles are mechanically broken under the action of a blender, and particles with lower wet content and smaller particles are clamped up by a rotating air stream. They are further dried during the rise process because of the gas-solid phase. Rotate flow, The inertia of the solid phase is greater than that of the gas phase. The relative velocity of the solid phase is relatively large, and the heat transfer effect of the two phases is strengthened. Therefore, the aircraft has a high drying strength.

Engineering advantages:

1, highly specialized, large amount of treatment, fast drying rate, material after atomization of the surface area greatly increased, in the vacuum state, drying time is greatly reduced. 2, the equipment structure is simple, no vulnerable parts, low maintenance costs. 3, simple and stable operation, convenient control, can realize intelligent operations. 4, using different boiling point temperature, to achieve liquid separation. 5, adopts the special non-standard design atomizer, atomization, separation effect is good. 6, set chemical reaction, drying and one, one time complete the reaction, drying, optimize the performance of the equipment.

- 2016-08-06 > There will also be a new trend in the rice dryer market

- 2016-08-06 > Application of eight kinds of drying equipment in chemical and pharmaceutical industry

- 2016-08-06 > Application of spray drying desulphurization technology in protecting ecological environment

- 2016-08-06 > Comparison of Powder Rate between Special Application and High Speed Spray Drying Machine of Traditional Chinese Medicine

- 2016-08-06 > Common Fault and Maintenance of Belt Dryer in Operation

- 2016-08-06 > Application range and type selection of strip dryer

- 2016-08-06 > Development Status and Characteristics of High Efficiency Mixer for Calcium Carbonate Industry

- 2016-08-06 > Safe use of hot air circulation oven and four key points for attention

- 2016-08-05 > Design Methods of Four Technologies for Rotating Flash Drying Machine